DriveMod Autonomous Tugger

Tugger Train AutomationWe've partnered with Motrec, a world-class tow tugger manufacturer to ensure that our autonomous tuggers can do the most demanding industrial jobs. Powered by our AI technology called DriveMod, our tuggers make intelligent, real-time decisions, enabling you to deploy a fully automated tugger train with multiple tugger carts.

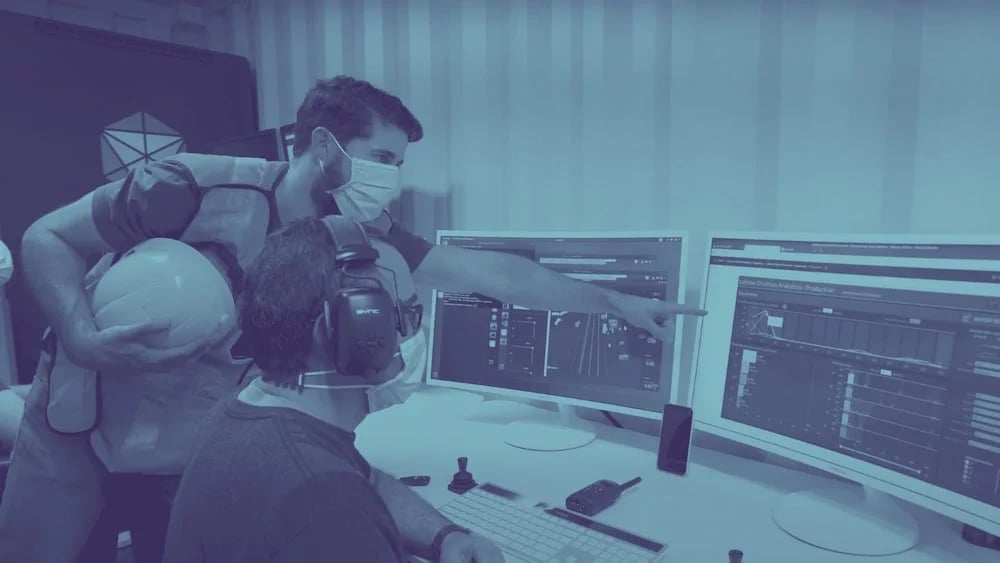

Streamline Your OperationsAutomate repetitive hauling workflows such as transferring finished goods or delivering supplies while reducing costly safety incidents. Free your team up to focus on other responsibilities to maximize your output.

Ensure Safe Handling of LoadsWith its all-steel unibody construction chassis, steel body panels, and standard dual-tire front fork, it boasts ruggedness, stability, and agility. Its smooth driving and precise movements ensure efficient handling of heavy loads up to 6,000 pounds.